Release time:2023-11-12 15:31:17 Hits: Current position: Home > News

This article mainly introduces:

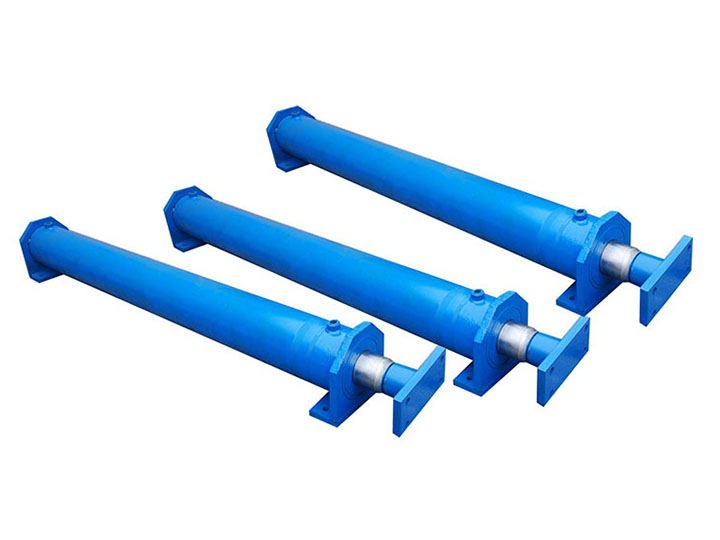

Croatia hydraulic cylinder,push and pull the cylinder manufacturer,push and pull the cylinder

(Croatia push and pull the cylinder,produced by Hengyu Hydraulic Cylinder Factory)

push and pull the cylinder are widely used in Croatia,because of high work efficiency,excellent fatigue and impact resistance,no need for deceleration device.So our company has designed push and pull the cylinder for customers from Croatia.

Repair method of small range wear of oil push and pull the cylinder: 1. Use oxygen-acetylene flame to bake the scratched part (master the temperature, avoid surface annealing), bake the oil on the metal surface all the year round until no sparks splash; 2. The scratched part is treated with an Angle grinder, the grinding depth is more than 1 mm, and the groove is polished along the guide rail, preferably a dovetail groove. Scratch both ends of the drilling deeper, change the force situation; 3. Clean the surface with absorbent cotton dipped in acetone or anhydrous ethanol.

In recent years, the processing process of the push and pull the cylinder generally adopts the rolling method, which is a pressure finishing processing, which uses the cold plastic characteristics of the metal at room temperature, and uses the rolling tool to exert a certain pressure on the surface of the workpiece, so that the surface metal of the workpiece produces plastic flow, and fills in the low concave trough of the original residue, and the roughness value of the workpiece surface is reduced. Due to the plastic deformation of the rolled surface metal, the surface tissue is cold hardened and the grain is fine, forming a dense fiber, and forming a residual stress layer, and the hardness and strength are increased, thus improving the wear resistance, corrosion resistance and compatibility of the workpiece surface. Rolling is a plastic machining method without cutting.

The piston rod and guide sleeve function of the push and pull the cylinder is crucial: the relative motion pair between the piston rod and the guide sleeve is the main factor causing external leakage, if the chrome layer on the surface of the piston rod is spalling or producing longitudinal tensile marks due to wear, it will directly lead to the failure of the seal.

push and pull the cylinder body inspection: The inner surface of the push and pull the cylinder and the piston seal are the main factors causing the leakage in the push and pull the cylinder, if the push and pull the cylinder has a longitudinal tensile mark, even if the new piston seal is replaced, it can not effectively eliminate the fault, the inner surface of the push and pull the cylinder mainly checks whether the dimensional tolerance and shape and position tolerance meet the technical requirements, there is no longitudinal tensile mark, and measures the depth of the longitudinal tensile mark, in order to take the corresponding solution.

What is the cause of the deep scratch of the cylinder?

The following reasons can cause the cylinder to be scratched. 1: Hydraulic oil containing particulate impurities into the hydraulic cylinder, these particulate impurities stuck between the piston rod and the guide ring (or stuck between the piston and the inner wall of the cylinder), when the piston movement in the cylinder will scratch the piston rod, the phenomenon of the inner wall of the cylinder, the more particles, the larger the scratch marks the deeper and more obvious. 2: The body of the cylinder itself. Due to assembly or design reasons, the coaxial error between the piston rod, piston, cylinder, guide ring and other parts is too large, or the cylinder, piston rod straightness error is too large, so that the piston rod and the guide ring interference between the cylinder, this mechanical interference will certainly lose the piston rod or cylinder wall.

How many boom cylinders, bucket rod cylinders and bucket cylinders are there in a small single-bucket excavator?

one for bucket, one for forearm, only one piece for a small excavator under the big arm, two pieces for medium and large excavator.